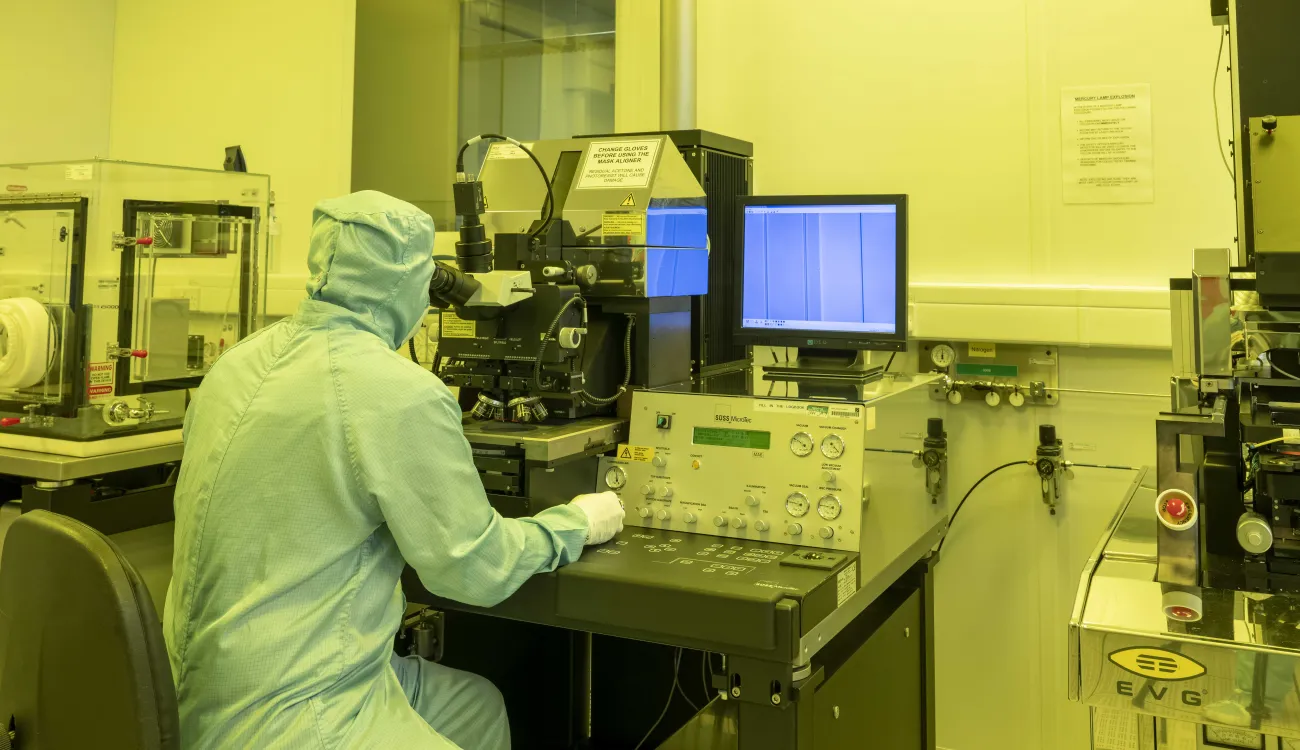

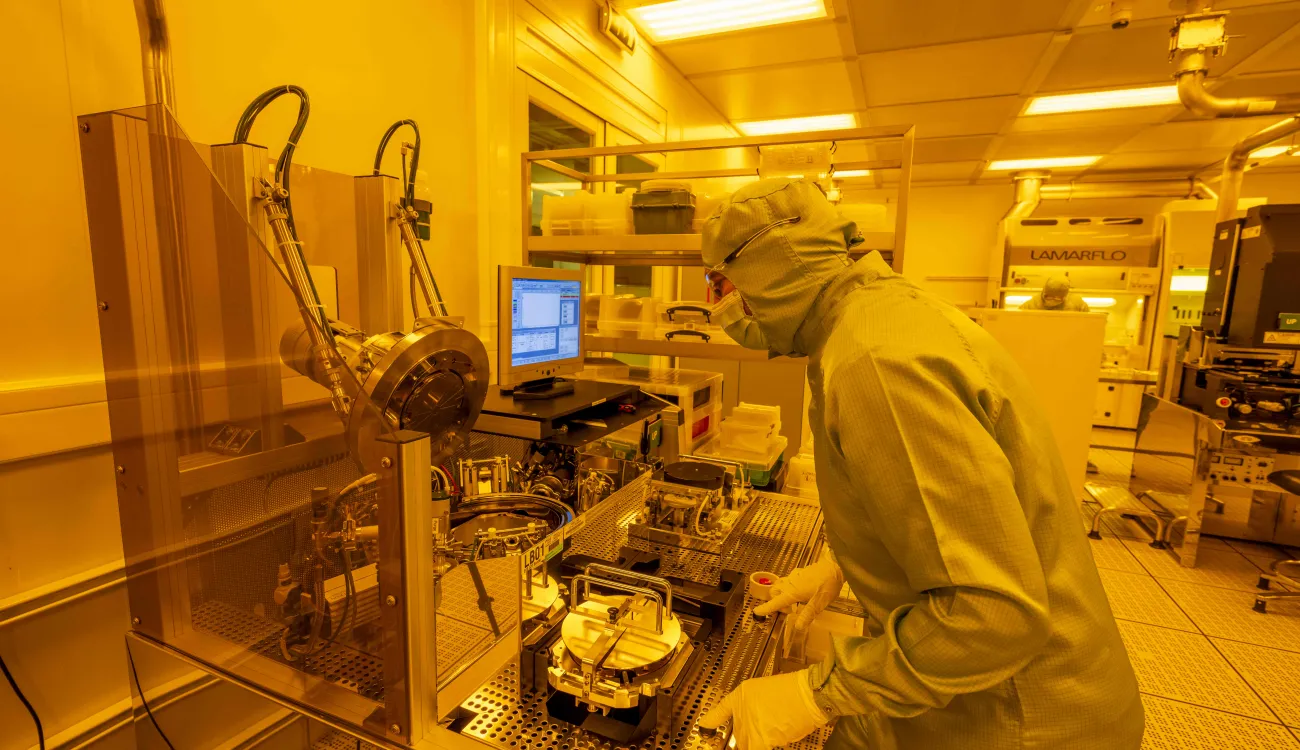

Part of the nanofabrication cleanrooms

Lithography is the technique by which design patterns are transferred to a sensitive resist at multiple stages of the fabrication process.

Our lithography capability features leading Electron Beam Lithography (EBL), writing to 5 nanometres (nm) feature size. Unique to UK academic research we also have a Deep Ultraviolet (248nm) scanner for feature size down to 180nm.

We also provide traditional broadband UV photolithography using manual mask aligners, for feature size down to 1 micrometre (µm).

The mask aligners operate in contact or proximity modes. They handle a range of substrate sizes, from small pieces up to 200 millimetre (mm) wafers, in front and backside alignment modes. We can fit the aligners with optical filters to allow G/H/I line wavelength selection.

Alternative nanopatterning techniques such as microcontact printing and nano imprint lithography are also available.

Our wafer bonder can perform pre-bond alignment via a mask aligner. This achieves micron-scale bond alignment accuracy.

We offer a versatile capability for resist processing, including multiple spin, bake, and development lines.

We work with many types of resists including:

- positive and negative tone UV photoresists

- electron beam resists

- thick film photoresists up to 100µm

- SU-8 epoxy photoresists

- laminated epoxy and acrylic photosensitive materials

Processes and equipment

Spin and bake

- CEE Apogee modules for separated optical and electron beam resist spin and bake

Optical photolithography (Broadband/G/H/I Line compatible)

- EVG620 & Karl Suss MA6 Broadband contact aligners

- 200mm frontside alignment

- 200mm front to backside alignment, bonding alignment, UV nanoimprint processes. Minimum standard feature size 1µm

- optimised for positive, negative, and LoF resists, polymers (SU-8, bonding)

- substrate sizes up to 200mm (other chucks available to handle smaller substrates)

Wafer bonding

- EVG 520 capable of performing thermo-compression, Fusion, Anodic, Eutectic and Adhesive bonding

- process temperature up to 500°C

- contact force up to 20 kilonewtons

- substrate sizes from pieces to 150mm wafers

- compatible with EVG 620TB for pre-bond wafer alignment

Resist processing

- optimised processes for scanner, e-beam, and optical lithography applications

- established positive, negative, lift-off, and image reversal resist processes

- polymer and spin-on glass coatings for bonding, structural materials, microfluidics, and encapsulation

- thickness ranges from nm to > 100µm

- dedicated resist spinners

- 300°C maximum temperature hotplate for substrates up to 200mm

- dehydration and resist bake ovens

- mask cleaner and lift-off station

- O2 microwave plasma ashing

- dedicated wet resist strip stations

Contact us

For more information or to book the facilities, get in touch: zepler.cleanrooms@soton.ac.uk