About the Geotechnical Centrifuge

Our Geotechnical Centrifuge Facility (GCF) consists of a 6m diameter geotechnical centrifuge and associated sample and model preparation facilities. These are used to undertake scaled physical model tests. The centrifuge spins the scale models to accelerations of up to 130 times Earth’s gravity.

Geotechnical centrifuges enable failure mechanisms and soil-structure interactions to be studied using real soil samples at small scale. This allows accelerated scale modelling of geosystems, such as earthworks, foundations and other civil engineering infrastructure that interacts with the ground.

Our research addresses the resilience and sustainability of offshore and onshore infrastructure, addressing engineering challenges on land, by the coast and at the seafloor. These range from wind farms to high speed rail systems, and from characterisation of microscopic soil properties through to the whole life behaviour of foundations and earthworks over decades of loading and climate impact.

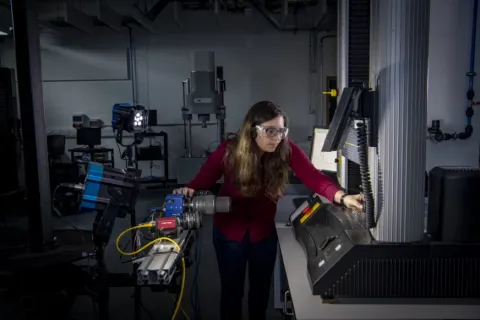

Our Geotechnical Centrifuge Facility (GCF) is part of the National Infrastructure Laboratory. Our facility is equipped with state-of-the-art systems for robotic control, data acquisition, image analysis and sample characterisation.

Our staff have supervised more than 40 PhDs involving centrifuge modelling, and we have collaborated with a wide range of infrastructure stakeholders to apply centrifuge modelling to their challenges.