Vibrations in Space - Application to Satellite Truss Design

The

OPTIONS

Design Exploration System has been applied to the design of

satellite trusses with enhanced vibration isolation characteristics.

The designs are based on a structure assembled by NASA astronauts

and were produced using Genetic Algorithm methods and a highly customized

vibrational energy flow code.

This kind of design may be of use in future

space infrared interferometer - planet finding missions.

Truss in Orbit

NASA STS61B-120-052, 27/11/85

The NASA `Assembly Concept for Construction of Erectable Space Structures'

(ACCESS) consisted of a tower like device which was built out from

the payload bay of the shuttle Atlantis in November 1985 by astronauts

Sherwood C. Spring and Jerry L. Ross.

Simplified 2d Model of Truss

Initially, a two-dimensional version of the truss was used for analysis.

This consisted of 40 beams and only in-plane vibration transmission

was considered.

Optimized 2d Model of Truss

Application of the Genetic Algorithm (GA) method within the OPTIONS package, using

4500 design evaluations spread over 18 generations, produced an optimized

design with a predicted vibrational energy transmission reduced by 60dB

over a 100Hz bandwidth. The GA was run in parallel on a heterogeneous

collection of single and multi-processor workstations over a two week period.

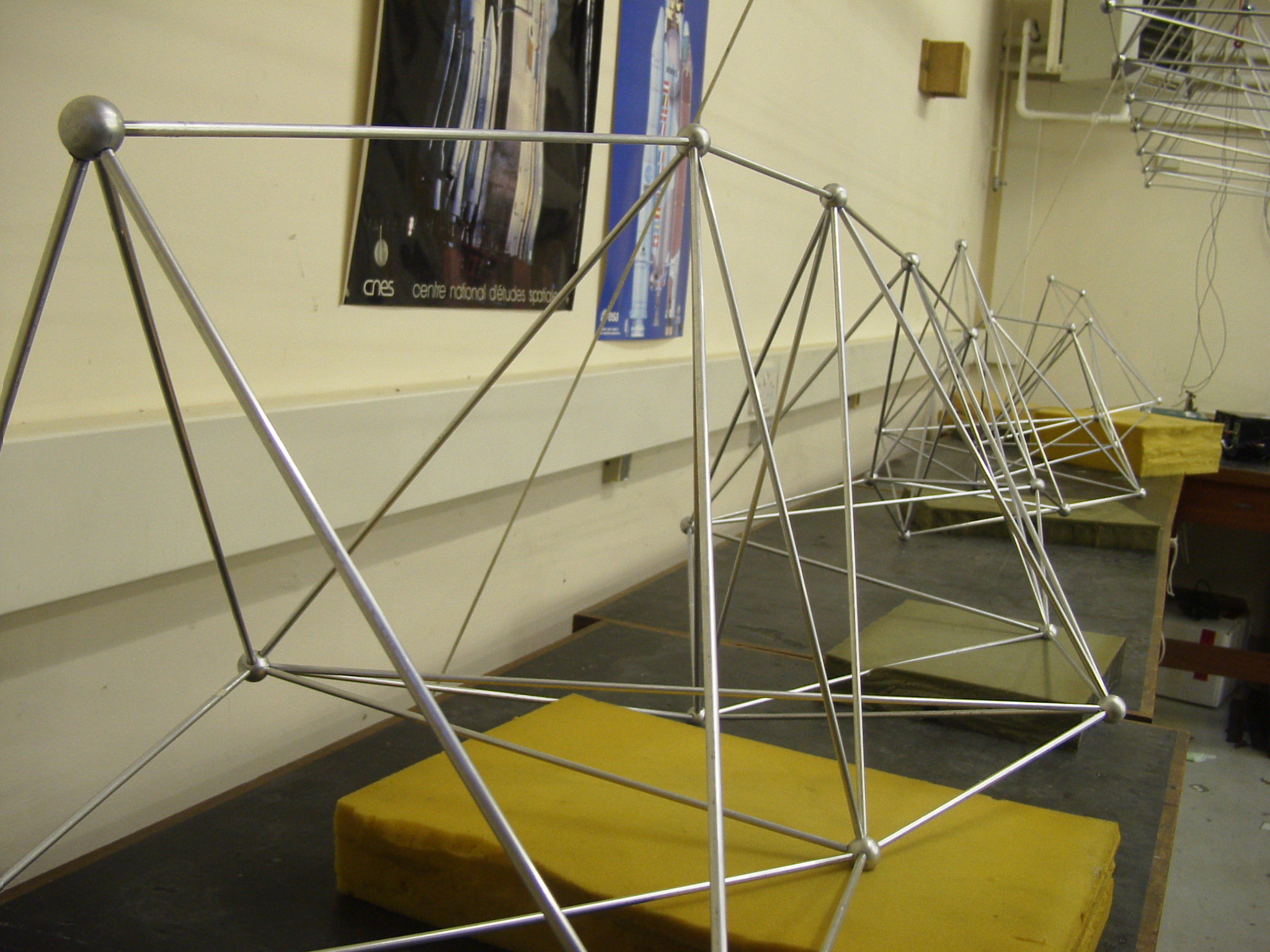

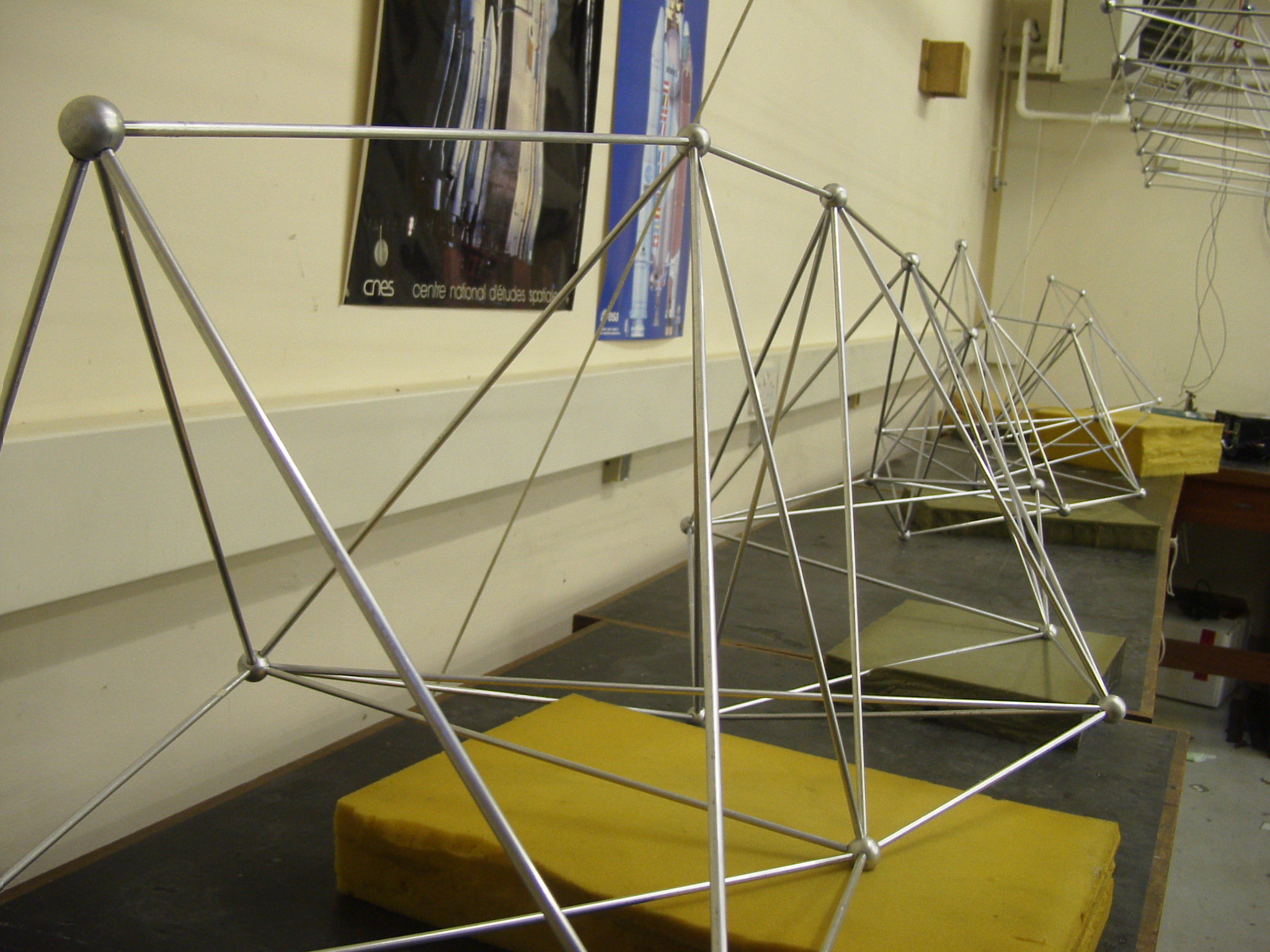

Optimized 2d Structure on Test

A scale model of the optimal structure was subsequently built and tested

alongside a model of the non-optimized design to see if the predicted

improvements could be realised in practice.

Frequency Response of 2d Structure

Measurements taken on the non-optimized and GA optimized designs

verified that the predicted improvements could be obtained in practice.

The correlation between theory and practice owed much to the use of

a specifically designed analysis code and careful choice of the precise quantities being

controlled by the optimizer.

Simplified 3d Model of Truss

Work is now in progress on optimizing a full 3-dimensional structure,

again using a parallel, multi-workstation GA. The structure consists of 120 individual beams

and allows for bending, axial and torsional vibrations of the

structure. The analysis used has been fully validated against detailed finite

element models of the structures constructed with commercial FE codes.

Optimized 3d Model of Truss

The initial designs produced by the optimization process again show significant

improvements in vibration isolation but would clearly be more difficult

to build and deploy in space than conventional designs. Nonetheless, given

that the improvements in vibration control are achieved without weight

penalties and only using passive methods, it would seem that this approach

has much to commend it.

Full references for papers describing this work and a number of related subjects may be found

on the home page of Prof. A.J. Keane (http://www.soton.ac.uk/~ajk/welcome.html ).

This article may be found at

http://www.soton.ac.uk/~ajk/truss/welcome.html